High temperature double –sided adhesive resistant tape

Sea 5 high temperature double-sided adhesive is made of special acrylic pressure sensitive adhesive. It has high temperature resistance, heat resistance, anti-rebound, warpage, and strong adhesive force and retention. Easy to assemble

Main Application:

Electronic components, IC , CPU ,MOS

LED ,DVD ,etc.

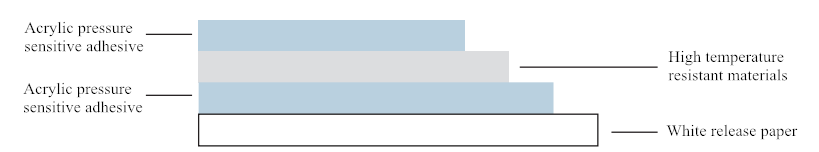

Product Structure:

Technical Data:

| Basic material | High temperature resistant materials |

| Total thickness: | 0.20 mm Tolerance ± 0.01 mm |

Width: | 1030 mm Tolerance≥ 1030 mm |

| Length: | 50M Tolerance≥ 50 mm (or customer spec). |

Initial tack adhesion(ball test) | ≥ 18N/in² GB/T 31125-2014 |

Holding Force | ≥ 48H/1kg/in² GB/T 4851-2014 |

| Temperature resistance | --20~180℃ GB/T 2941-2006 |

| The color of release paper: white |

IMPROTANT:

◆Please keep the surface to be adhered clean before use, no stains, oil stains, water stains

◆The best storage temperature is 23 ± 2 °C, the best operating temperature is 18 °C to 25 °C, if less than this Please use temperature before baking (40°C/24H) or lengthen curing time after bonding

◆To achieve better adhesion, apply sufficient pressure during bonding (we recommend 4KG uniform pressure) and provide sufficient curing time after bonding (tests show that the adhesive tends to maximize after 72 hours With stability, premature load carrying capacity should be avoided)

◆Working environment: must be ventilated at normal temperature, clean work The space temperature for preservation and operation cannot be ≥85% to ensure product stickiness

◆Storage temperature is too high (> 40 °C) will cause the use of reduced adhesion, such as exposure to sunlight can easily cause release of silicon transfer material caused by tape viscosity decreased or even no stickiness

◆Storage temperature is too low (< 18 °C) will cause the use of initial adhesion reduction, such as less than 10 °C stored in the use of plastic surface frost easily affect the adhesive effect

◆Important tips :The test data provided above are average values and are for reference only. Due to the diversification of materials used by customers and the impact of the operating environment, we are not able to provide any applicability guarantee. It is recommended that the customer conduct detailed inspection before use and whether the tape meets all your requirements.